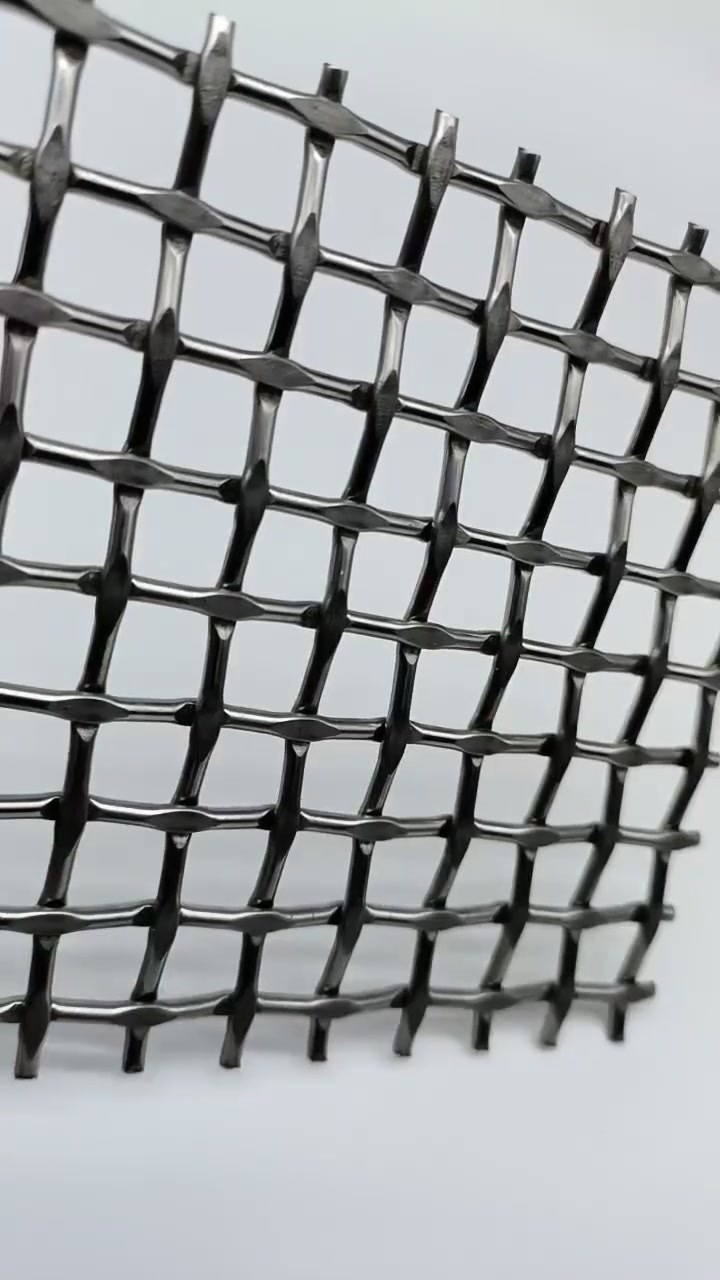

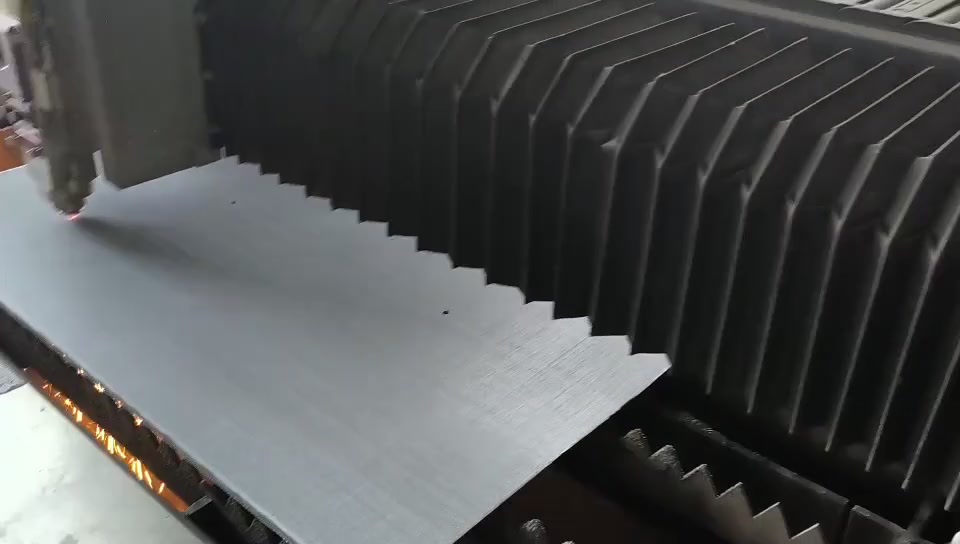

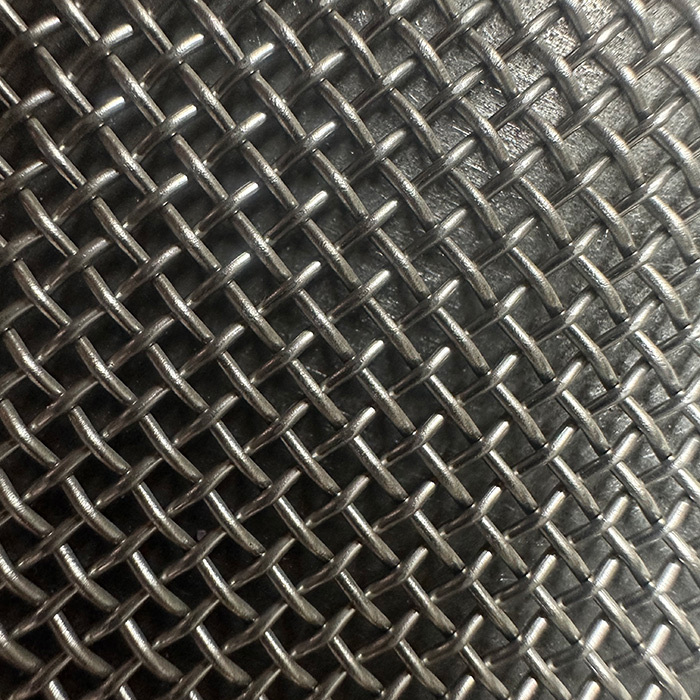

Stainless steel sintered filter element

It can be used to filter crude oil and various liquids in the refining process, such as gasoline, diesel, lubricating oil, etc., to remove solid particles, mechanical impurities, moisture, etc., to improve the quality of oil products; it can also be used for filtering various high-temperature and corrosive liquids, such as in the catalyst filtering and washing process, to remove impurities in the catalyst to ensure the activity and service life of the catalyst.

Classification:

Sintered filter element

PRODUCT DETAILS

Uses of stainless steel sintered filter element/filter cartridge:

Industrial field:

Petrochemical industry: It can be used to filter crude oil, various liquids in the refining process, such as gasoline, diesel, lubricating oil, etc., to remove solid particles, mechanical impurities, moisture, etc., to improve the quality of oil products; it can also be used for filtering various high-temperature, corrosive liquids, such as in the catalyst filtration and washing process, to remove impurities in the catalyst to ensure the activity and service life of the catalyst.

Pharmaceutical industry: In the pharmaceutical process, it is used for decarbonization filtration in the concentrated preparation of large infusions, small injections, and oral liquids, and security filtration before terminal filtration in the dilute preparation process; impurity removal filtration, material decarbonization filtration and fine filtration in the production process of raw materials; filtration of injection liquid, bottle washing water, etc., to ensure the safety and purity of drugs.

Chemical fiber and textile industry: used for acid bath filtration, sodium thiocyanate purification filtration, silk weaving water precision filtration, etc., to remove impurities and pollutants generated in the production process and improve product quality.

Electronic industry: In the production process of electronic products, it is used to filter electronic chemicals, photoresists, etc., to remove tiny particles and impurities, and ensure the production quality of electronic products. For example, in the semiconductor manufacturing process, particles in the chemical mechanical polishing liquid can be filtered to prevent damage to the chip surface.

Metallurgical industry: used for filtering various liquid metals in the metal smelting process, removing impurities and non-metallic inclusions, and improving the purity of the metal; it can also be used for the purification of high-temperature furnace gas and the recovery of valuable metal dust.

Mechanical processing industry: used for filtering various lubricating oils and hydraulic oils, removing impurities and wear particles in the oil, ensuring the normal operation of mechanical equipment and extending the service life of the equipment.

Environmental protection field:

Sewage treatment: installed in sewage treatment equipment, filtering out solid impurities, suspended matter, organic matter, etc. in sewage, so that the treated water meets the discharge standards; it can be used for various sewage treatment scenarios such as industrial wastewater and domestic sewage, and has a good filtering effect on wastewater containing heavy metal ions, acids and alkalis and other harmful substances.

Gas purification: used for purification of industrial waste gas and tail gas, removing dust, particulate matter, harmful gases and other pollutants in the gas, reducing pollution to the environment; for example, in the dust removal of high-temperature flue gas generated in industrial production processes such as steel mills, cement plants, and power plants, sintered filter elements can withstand high temperatures and have good filtering performance.

Food and beverage industry: used for filtration in the production process of food and beverages, such as clarification and filtration of beer, juice, liquor, wine, vegetable oil, mineral water, soy sauce, vinegar, etc., to remove impurities, sediments, microorganisms, etc., and improve the quality and safety of food and beverages.

Other fields: In the field of aerospace, it can be used for the filtration of aviation fuel and hydraulic oil, as well as the air filtration of aircraft engine intake systems; in the field of scientific research, it can be used for laboratory filtration, separation and other operations.

Specifications of sintered filter element:

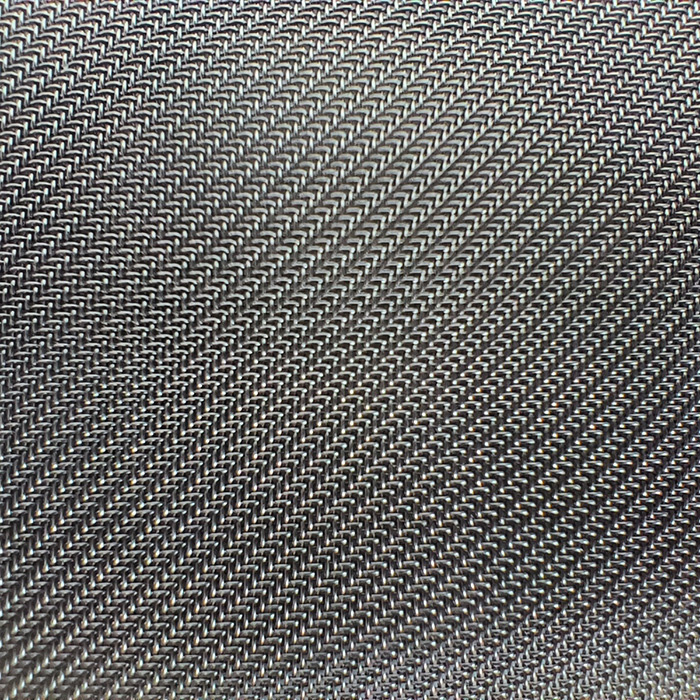

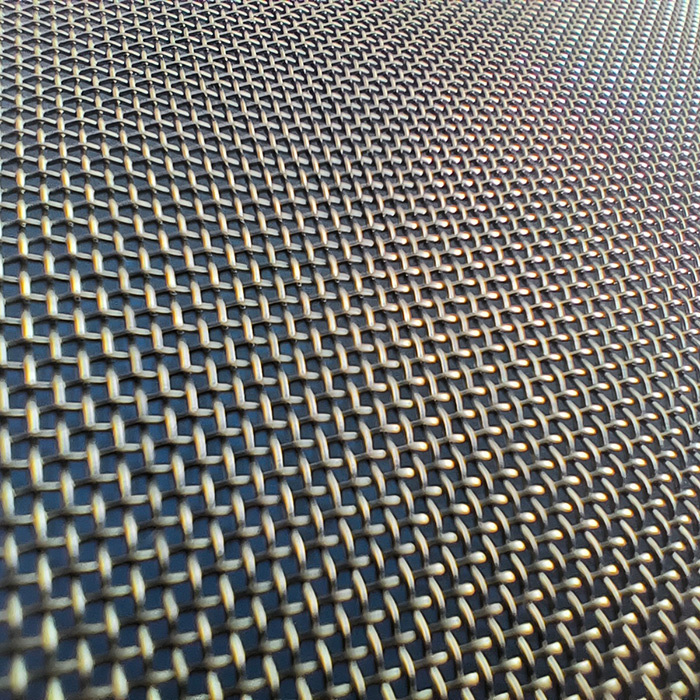

Material: Common materials include stainless steel (such as 304, 316, 316L, 310S, etc.), titanium, copper, polytetrafluoroethylene, glass fiber, etc. Different materials have different properties such as corrosion resistance, high temperature resistance and mechanical strength, which can be selected according to the specific use environment and requirements.

Filtration accuracy: The filtration accuracy range is wide, ranging from 1 micron to 300 microns, and even higher or lower filtration accuracy can be customized according to customer needs.

Size:

Diameter: Generally ranges from a few millimeters to tens of centimeters, and common ones are 10 mm, 25 mm, 35 mm, 50 mm, 60 mm, etc.

Length: Usually between 10 mm and 1200 mm, such as 5 inches (about 127 mm), 10 inches (about 254 mm), 20 inches (about 508 mm), 30 inches (about 762 mm), 40 inches (about 1016 mm), etc.

Thickness: The thickness is generally between a few millimeters and tens of millimeters, and the specific thickness depends on different filtration needs and usage scenarios.

Shape: It can be processed into various shapes such as cylindrical, disc, plate, funnel, etc. to meet the needs of different equipment and usage scenarios.

Interface form: Common interface forms include threaded interface, flange interface, bayonet interface, etc., which are convenient for connection with different filtering equipment

Key words:

Stainless steel mesh、Sintered mesh、Filter element、Nickel Mesh & Copper Mesh

Previous

Previous

RELATED PRODUCTS

CONSULTATION

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!

WhatsApp:

Tel:

Address:

No.52, Weier Road, high tech Industrial Development Zone, Anping County, Hengshui City, Hebei Province

Copyright © kangxinlong wire mesh Manufacturing Co., Ltd. Powered by:www.300.cn SEO license