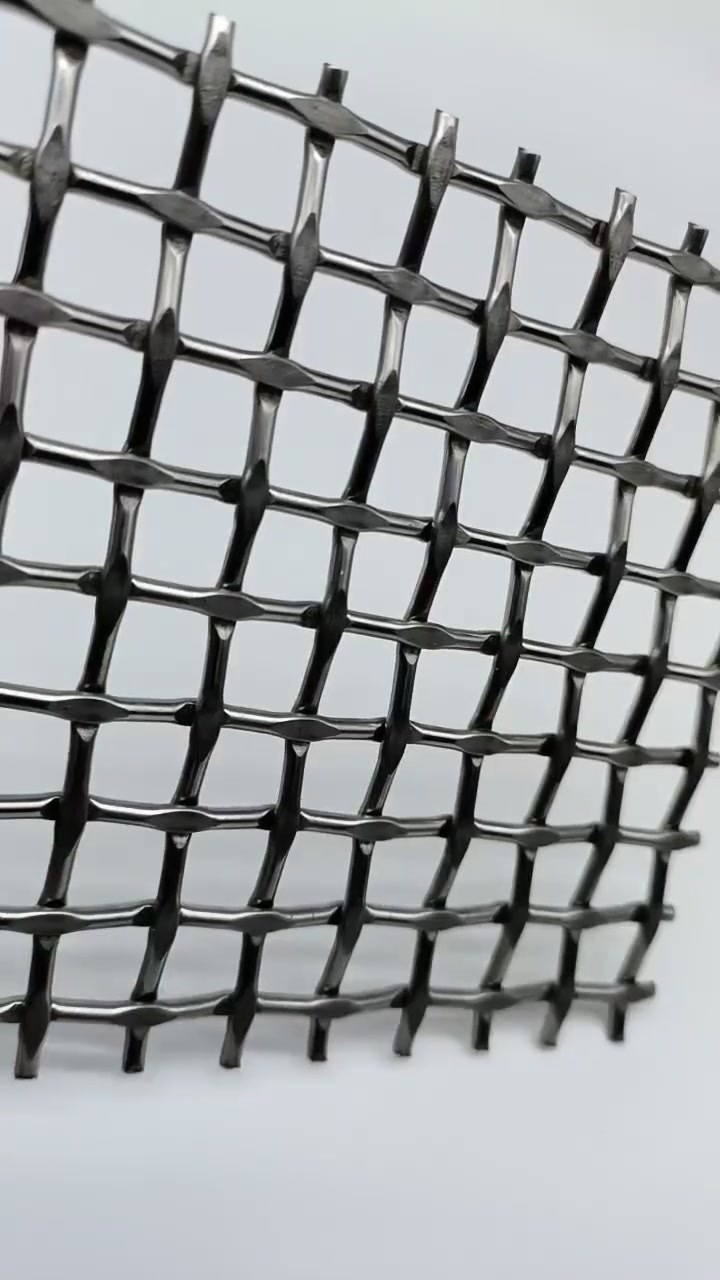

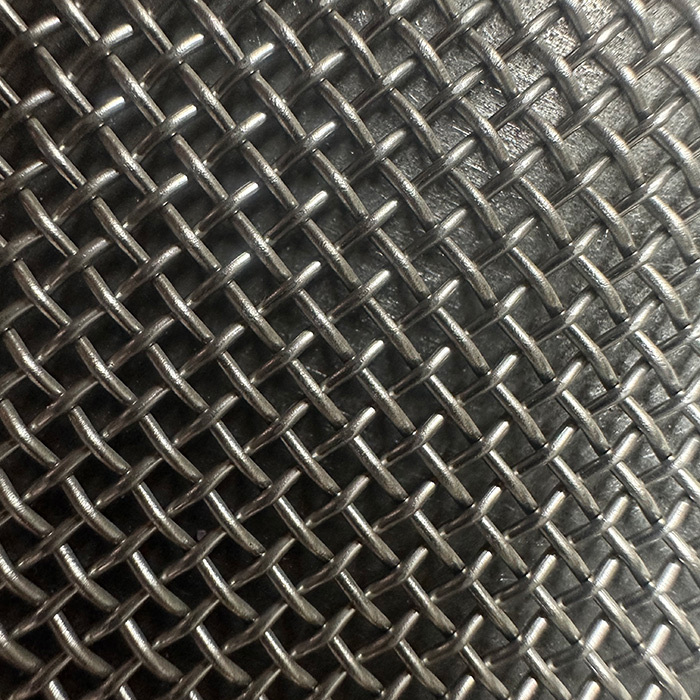

Hastelloy Alloy Fiber Sintered Felt

Filter and purify various polymer melts to remove impurities, gels, unreacted monomers, etc., to ensure the purity and quality of the polymers, and thus produce high-quality chemical fiber products. For example, in the production process of polyester fibers, stainless steel sintered felt can be used to filter polyester melts to prevent impurities from affecting the performance of the fibers.

Classification:

Sintered Felt

PRODUCT DETAILS

Industrial filtration field:

Chemical fiber industry: Filter and purify various polymer melts to remove impurities, gels, unreacted monomers, etc., to ensure the purity and quality of the polymers, and thus produce high-quality chemical fiber products. For example, in the production process of polyester fibers, stainless steel sintered felt can be used to filter polyester melts to prevent impurities from affecting the performance of the fibers.

Petrochemical industry: Used to filter various liquids in crude oil and oil refining processes, such as gasoline, diesel, lubricating oil, etc., to remove solid particles, mechanical impurities, moisture, etc., to improve the quality of oil products. At the same time, it can also be used to filter various corrosive liquids in chemical production processes, such as acids, alkalis, organic solvents, etc.

Electronic industry: In the electronics industry, it is used to filter electronic chemicals, photoresists, etc., to remove tiny particles and impurities, and to ensure the production quality of electronic products. For example, in the semiconductor manufacturing process, stainless steel sintered felt can be used to filter chemical mechanical polishing liquid (CMP slurry) to prevent particles from damaging the chip surface.

Pharmaceutical industry: Used to filter various liquid medicines in the pharmaceutical process, such as antibiotics, Chinese medicine extracts, etc., to remove impurities, bacteria, heat sources, etc., to ensure the safety and effectiveness of drugs.

Food and beverage industry: used for filtration in the production process of food and beverages, such as filtration of beer, juice, edible oil, etc., to remove impurities, sediments, microorganisms, etc., and improve the quality of food and beverages.

High-temperature gas dust removal field: can be used for dust removal of various high-temperature gases, such as high-temperature flue gas dust removal generated in industrial production processes such as steel plants, cement plants, and power plants. Stainless steel sintered felt can withstand high temperatures and has good filtering performance. It can effectively remove impurities such as dust and particulate matter in high-temperature gases and reduce pollution to the environment.

Hydraulic system filtration field: in hydraulic systems, it is used to filter hydraulic oil, remove impurities, wear particles, etc., and ensure the normal operation of the hydraulic system. Stainless steel sintered felt has high strength and corrosion resistance, and can withstand the high pressure and impact of the hydraulic system while maintaining good filtering performance.

Catalyst carrier field: due to its high porosity and large specific surface area, it can be used as a catalyst carrier, so that the catalyst can be evenly dispersed on its surface, improving the activity and utilization rate of the catalyst. For example, in the process of automobile exhaust purification and catalytic reaction in chemical production, stainless steel sintered felt can be used as a catalyst carrier.

Other fields: It can also be used for fuel filtration, air filtration, etc. in aerospace, automobile, shipbuilding and other fields; in the field of environmental protection, it can be used for sewage treatment, waste gas treatment, etc.; in the field of scientific research, it can be used for laboratory filtration, separation and other operations.

Specifications of stainless steel sintered felt:

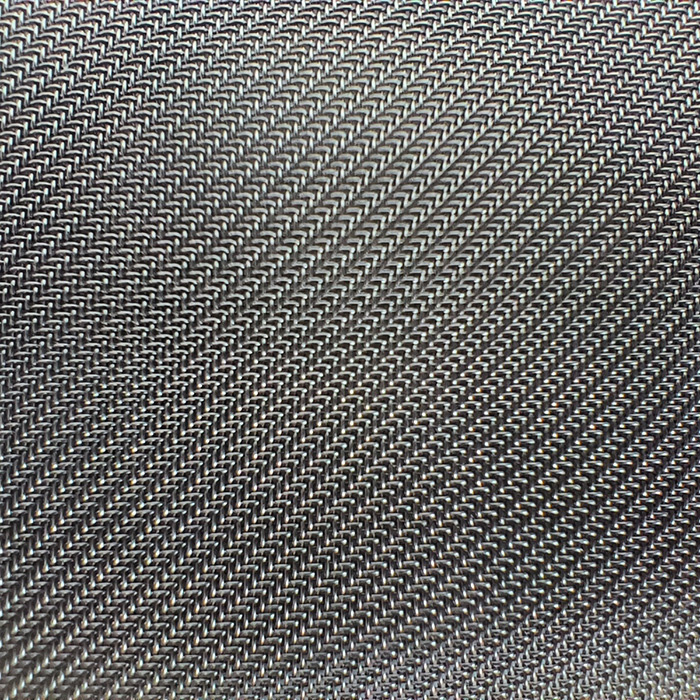

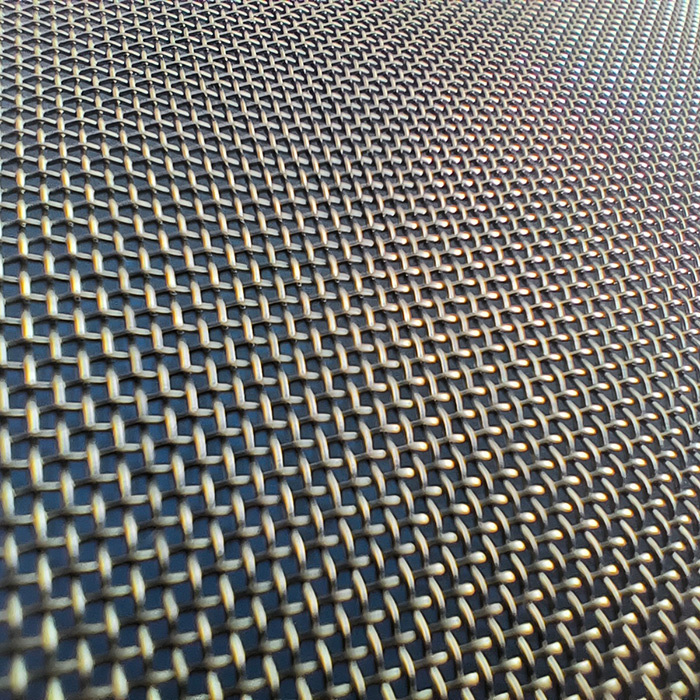

Material: Common materials include 304, 316, 316L, 310S, etc.

304 material has good corrosion resistance and processing performance, and the price is relatively low, which is suitable for general industrial filtration and use environment; 316 and 316L materials have stronger corrosion resistance, especially better tolerance to corrosive media such as chloride ions, and are suitable for some environments with high corrosion resistance requirements.

Filtration accuracy: The filtration accuracy range is wide, ranging from 1 micron to 300 microns, and even higher or lower filtration accuracy can be customized according to customer needs.

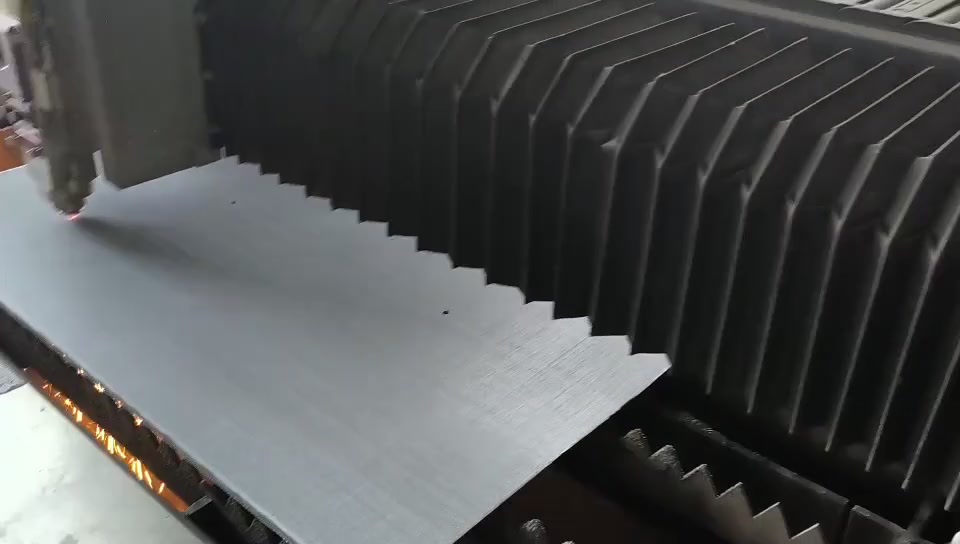

Size:

Regular size: Common sizes are 500mm×500mm, 1000mm×1000mm, 760mm*1000, etc.

Maximum size: Maximum size is 1600mm×1200mm

Key words:

Stainless steel mesh、Sintered mesh、Filter element、Nickel Mesh & Copper Mesh

Previous

Previous

RELATED PRODUCTS

CONSULTATION

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!

WhatsApp:

Tel:

Address:

No.52, Weier Road, high tech Industrial Development Zone, Anping County, Hengshui City, Hebei Province

Copyright © kangxinlong wire mesh Manufacturing Co., Ltd. Powered by:www.300.cn SEO license