Aggregate Screen

In the construction materials industry, sand, gravel and other construction materials are graded and screened. Sand of different particle sizes can be screened out for different construction project needs, such as fine sand for wall plastering and coarse sand for concrete production.

Classification:

Screen

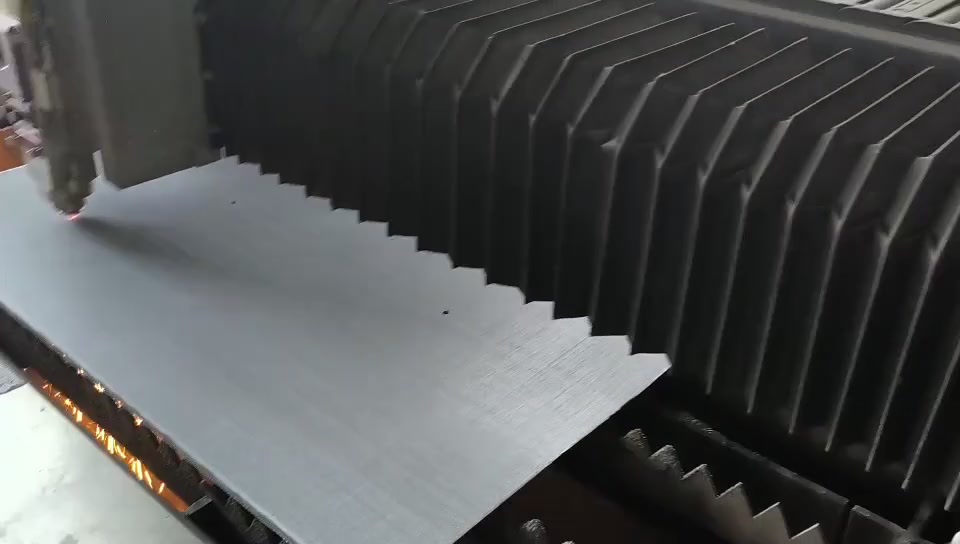

PRODUCT DETAILS

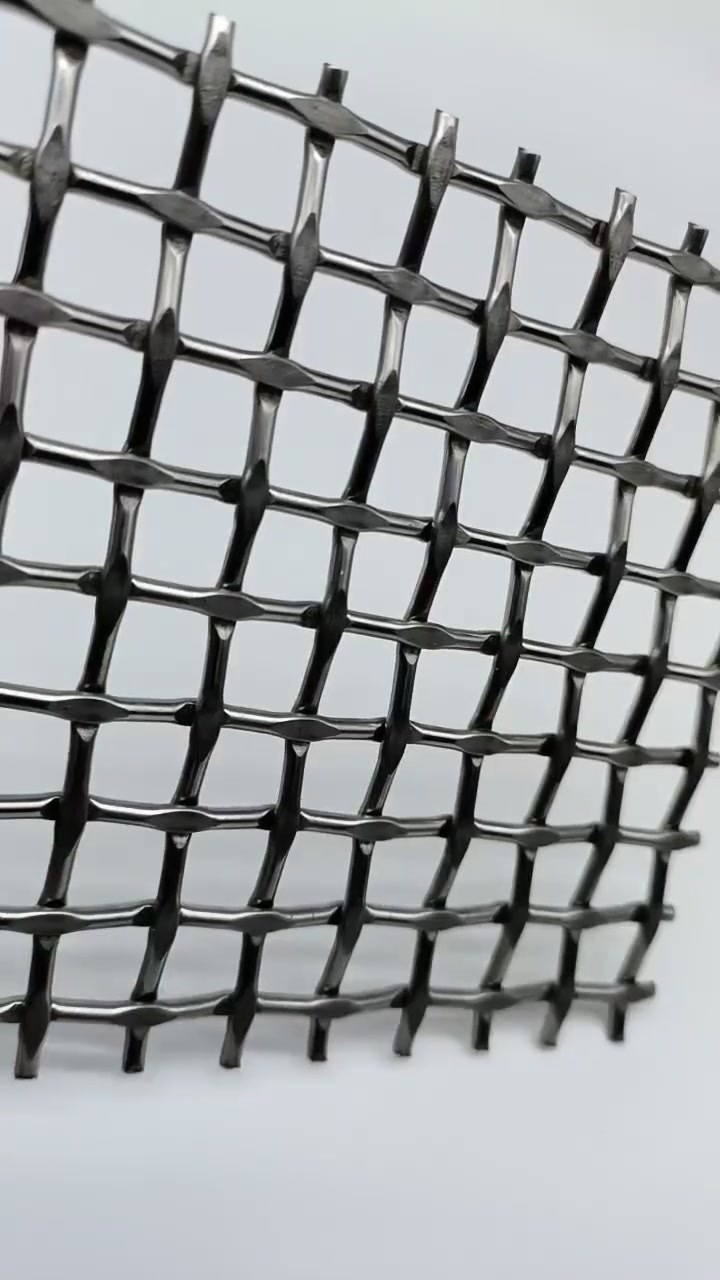

Woven mesh/screen introduction and specifications:

Weaving method of stainless steel mesh:

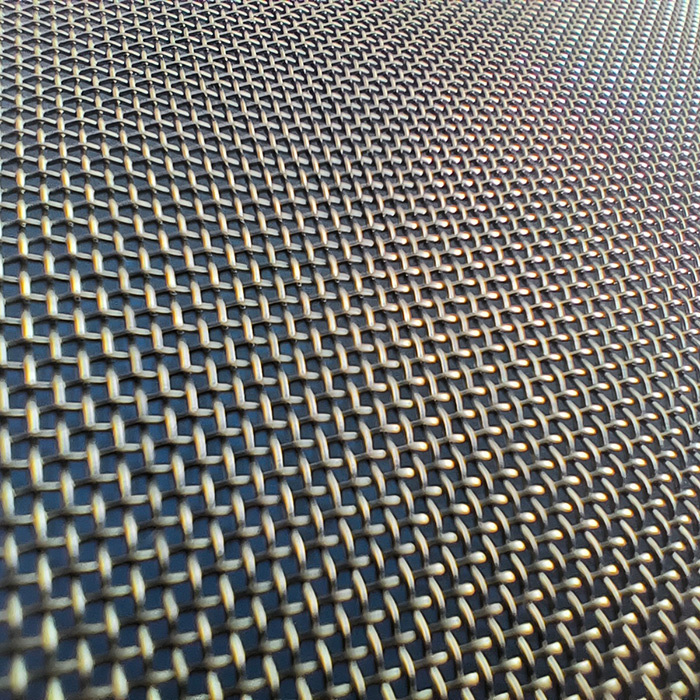

Plain weave:

The wire diameter density in the warp and weft directions is the same. The mesh size of this weaving method is uniform, the filtration accuracy is high, and the structure is stable. It is often used in occasions with high requirements for filtration accuracy.

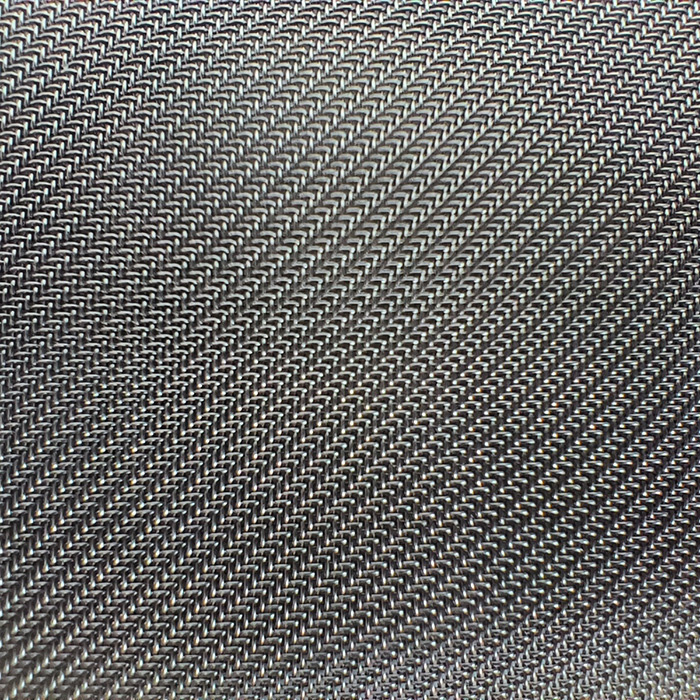

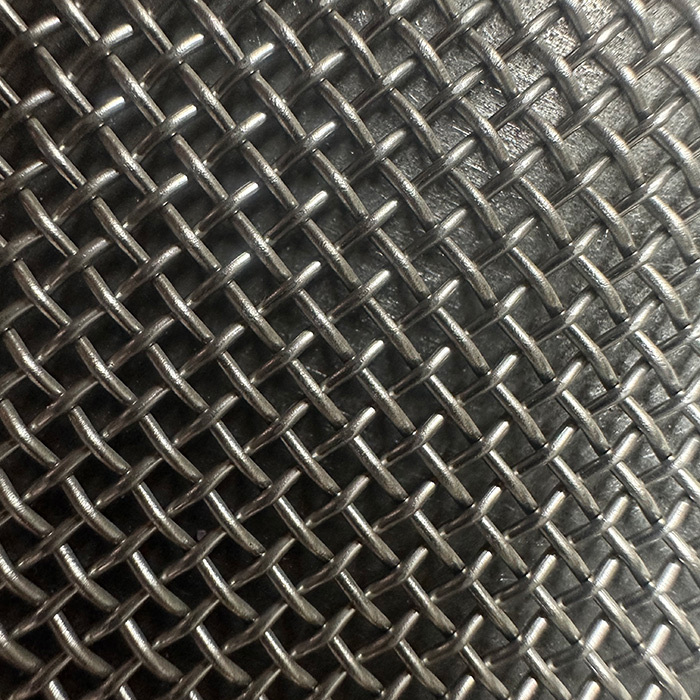

Twill weave:

The twill woven stainless steel screen has high strength and good flexibility. The mesh holes are arranged obliquely. Its filtration efficiency is relatively high, but the filtration accuracy may be slightly lower than that of the plain weave screen. It is often used in occasions that require certain strength and filtration efficiency.

Dense weave:

The dense weave screen has a finer wire diameter and smaller mesh holes. The filtration accuracy is very high. It can filter tiny particles and impurities. It is often used in fine filtration occasions with extremely high requirements for filtration accuracy.

Mat weave:

It is a more complex weaving method that combines the characteristics of plain and twill to form a special mesh structure with high strength and filtration accuracy. It is suitable for some special filtration and screening needs.

Width and length:

The width is generally between 1 meter and 10 meters, and the length can be customized according to customer needs. The common length is 30 meters, etc., but the specific size range will also vary depending on the manufacturer and equipment.

Application:

I. Industrial field

Filtration and separation

In the petrochemical industry, it is used to filter impurities, solid particles, etc. in crude oil. For example, in the refining process, crude oil is initially filtered to prevent large particles from entering the subsequent processing equipment, protect the equipment and improve product quality.

In the food and beverage industry, liquid raw materials such as milk and juice are filtered to remove impurities such as pulp residues and microorganisms to ensure the purity and taste of the product.

In the pharmaceutical industry, it is used for the filtration process in the drug extraction process to separate the active ingredients from impurities, and to filter the finished drugs in the final stage of drug production to ensure that the quality of the drugs meets the standards.

Screening and grading

In the mining field, ore is screened and graded. Stainless steel woven screens of different specifications can classify the ore according to the particle size, which is convenient for subsequent mineral processing, smelting and other processes. For example, in copper mining and processing, the copper ore particle size range that meets the smelting requirements is screened out through the screen.

In the building materials industry, sand, gravel and other building materials are graded and screened. Sand of different particle sizes can be screened out for different construction project needs, such as fine sand for wall plastering and coarse sand for concrete production.

Protection and safety

In machinery manufacturing, as a protective net for equipment, it prevents operators from accidentally contacting high-speed running parts and plays a role in safety protection. For example, stainless steel woven screen fences are installed around lathes, milling machines and other equipment.

In the power industry, as a protective net in places such as substations and distribution rooms, it prevents small animals from entering, avoids damage to electrical equipment, and ensures the safe operation of the power system.

2. Agricultural field

Seed screening

Used to screen seeds of different sizes and qualities. For example, in the processing of wheat seeds, full and uniform seeds can be screened out through stainless steel woven screens to increase the germination rate of seeds and the yield of crops.

Agricultural product processing

In the process of agricultural product processing, agricultural products are screened and filtered. For example, in flour processing, impurities such as bran in flour are sieved out; in tea processing, tea leaves of different grades are sieved out.

3. Home life area

Kitchen supplies

As a kitchen filter basket, filter, etc. For example, when washing vegetables and rice, a filter basket made of stainless steel woven screen can easily filter out water while leaving food in the basket.

Decoration and protection

It can be used to make guardrails for home decoration. For example, installing stainless steel woven screen guardrails in balconies, stairs, etc. not only plays a role in protecting safety, but also has a certain decorative effect.

Material:

Manganese steel stainless steel 201.304 .316 .316L .321. 310S.904L .2205. 2507. Nickel .Titanium .Hastelloy .Monel alloy .Nichrome alloy, etc.

Specifications:

Mesh number: Mesh number is an important specification indicator of stainless steel screen, which refers to the number of holes in a length of 1 inch (25.4 mm). For example, 4 mesh means there are 4 holes in a length of 1 inch. The higher the mesh number, the smaller the hole and the finer the particles that can pass through.

Common mesh range: Generally, 2 mesh to 500 mesh are more common, such as 10 mesh, 20 mesh, 30 mesh, 40 mesh, 50 mesh, 60 mesh, 80 mesh, 100 mesh, 120 mesh, 150 mesh, 200 mesh, 300 mesh, 325 mesh, 400 mesh, etc. are all commonly used mesh numbers.

Wire diameter: refers to the diameter of the stainless steel wire that makes up the screen, usually in millimeters. The thickness of the wire diameter will affect the strength, filtration accuracy and service life of the screen.

Common wire diameter range: ranging from 0.03 mm to 15 mm, and the appropriate wire diameter will be selected according to factors such as the purpose and mesh number of the screen16.

Aperture:

Definition: The distance between two adjacent wires on the screen determines the size of the particles that can pass through the screen. The unit can be millimeters or microns4.

Range: Common aperture sizes range from 10 microns to 10 mm. For example, the aperture of 80 mesh stainless steel wire mesh is approximately between 0.167 mm and 0.212 mm (the aperture corresponding to different wire diameters will be different)

Common specifications:

Aperture 1mm*wire diameter. 0.3-1mm

Aperture 2mm*wire diameter. 0.5-1mm

Aperture 3mm*wire diameter. 0.5-2mm

Aperture 4mm*wire diameter. 0.5-3mm

Aperture 6mm*wire diameter. 0.8mm-3.5mm

Aperture 7mm*wire diameter. 0.8mm-4mm

Aperture 8mm*wire diameter. 1mm-5mm

Aperture 10mm*wire diameter. 1.5mm-6mm

Aperture 12mm*wire diameter. 1.5mm-6mm

Aperture 15mm*wire diameter. 2mm-6mm

Aperture 20mm*wire diameter. 2mm-8mm

Aperture 25mm*wire diameter. 3mm-10mm

Aperture 30mm*wire diameter. 4mm-10mm

Aperture 40mm*wire diameter. 4mm-12mm

Key words:

Stainless steel mesh、Sintered mesh、Filter element、Nickel Mesh & Copper Mesh

Previous

RELATED PRODUCTS

CONSULTATION

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!

WhatsApp:

Tel:

Address:

No.52, Weier Road, high tech Industrial Development Zone, Anping County, Hengshui City, Hebei Province

Copyright © kangxinlong wire mesh Manufacturing Co., Ltd. Powered by:www.300.cn SEO license