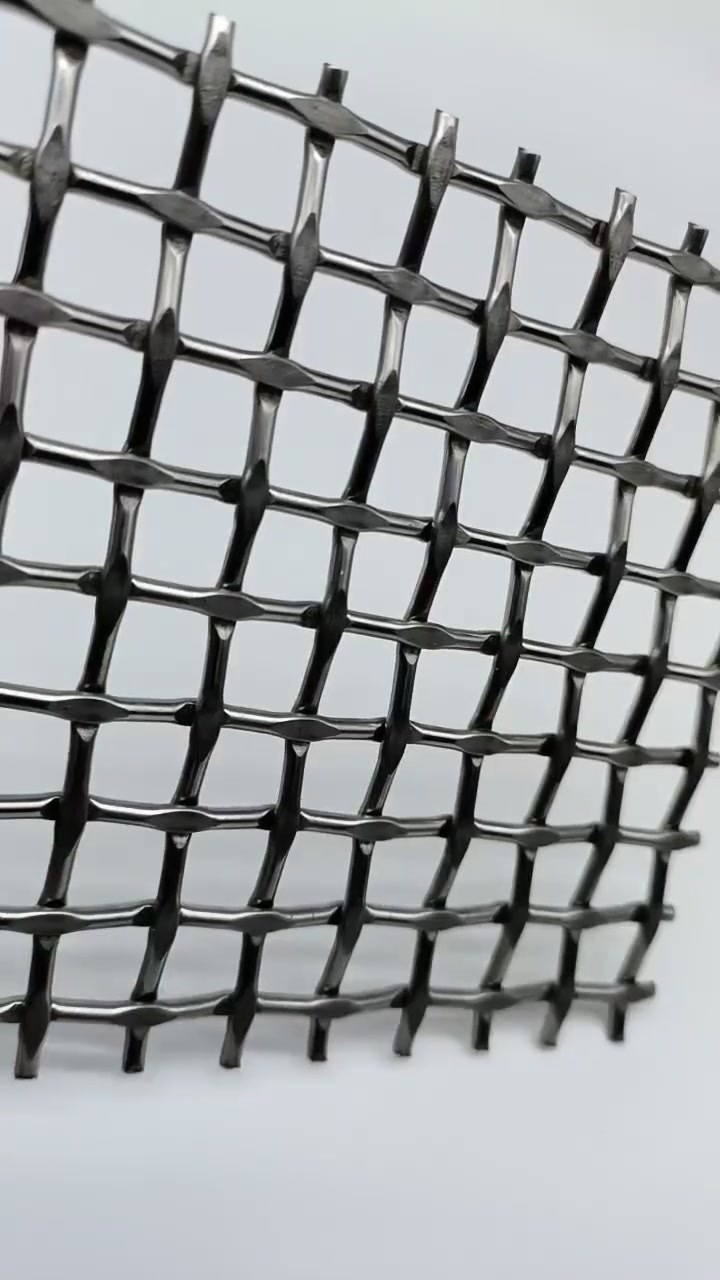

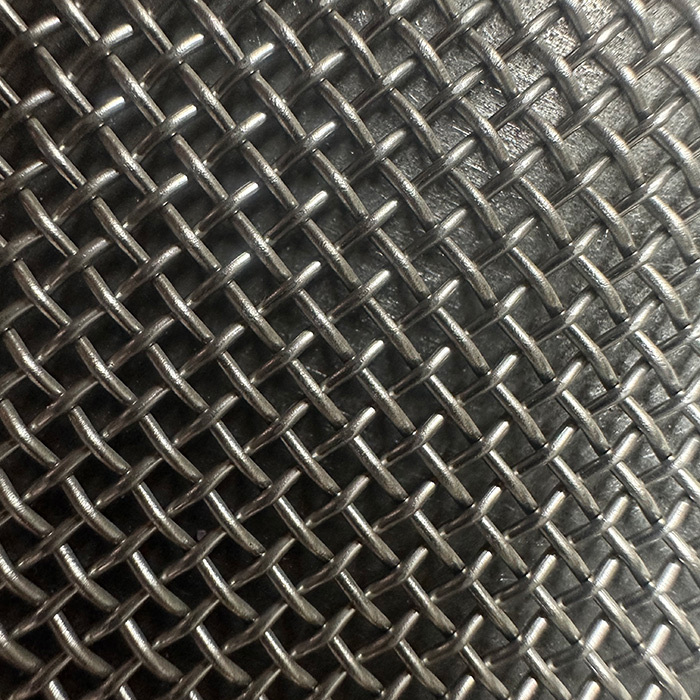

400 mesh screen

Used as a screen in the chemical fiber industry to screen and filter various chemical raw materials, intermediate products and finished products, separate impurities, particles, etc., to ensure the purity and quality of the products. For example, in the production process of synthetic fibers, solid particles in the synthetic liquid are filtered out to prevent them from affecting the performance of the fiber.

Classification:

Filter

PRODUCT DETAILS

Uses and specifications of stainless steel filter mesh

Uses of stainless steel filter mesh:

Industrial field:

Chemical industry: Used as a screen in the chemical fiber industry to screen and filter various chemical raw materials, intermediate products and finished products, separate impurities, particles, etc., to ensure the purity and quality of the products. For example, in the production process of synthetic fibers, solid particles in the synthetic liquid are filtered out to prevent them from affecting the performance of the fiber.

Petroleum industry: Used as a mud net to filter the mud during oil extraction, remove impurities such as rock debris and sand in the mud, and ensure the smooth progress of drilling operations. In the process of oil refining, it can also be used to filter impurities in crude oil and improve the quality of refined products.

Mining field: In the process of mineral processing, the ore is screened and graded, and the ores of different particle sizes are separated to facilitate subsequent mineral processing and processing. For example, in coal mining, coal particles that meet the particle size requirements are screened out.

Electronic industry: Used for cleaning and filtering in the production process of electronic products, such as in semiconductor manufacturing, filtering out tiny particles in the air to prevent them from affecting the chip manufacturing process.

Electroplating industry: As a pickling net, during the pickling process before electroplating, it prevents impurities on the surface of the workpiece from entering the pickling solution and affecting the electroplating effect.

Environmental protection field:

Wastewater treatment: Installed in sewage treatment equipment, filter out solid impurities, suspended matter, etc. in sewage, so that the treated water meets the discharge standards. For example, in urban sewage treatment plants, stainless steel filters are important filtering components.

Air purification: Used in air filters to filter pollutants such as dust, pollen, and bacteria in the air to improve air quality. In industrial production workshops, hospitals, laboratories and other places with high requirements for air quality, the air purification function of stainless steel filters is particularly important.

Food processing field:

Screening and filtration: Screen and filter food raw materials to remove impurities, foreign matter, etc. to ensure food safety and hygiene. For example, in flour production, filter out impurities and bran in wheat; in juice production, filter out pomace and peel, etc.

Drying equipment: As a ventilation filter for food drying equipment, it ensures air circulation during the drying process and prevents food particles from entering the ventilation duct.

Construction field:

Building protection: used as a building protection net to prevent people and objects from falling from heights and ensure the safety of construction workers. Compared with traditional nylon protection nets, stainless steel protection nets have higher strength and corrosion resistance.

Architectural decoration: can be used for building decoration, such as making screens, partitions, etc., which are both beautiful and can play a certain protective role.

Home life field:

Kitchen utensils: such as kitchen water filter baskets, oil filters, etc., used to filter food residues, grease, etc. In small household appliances such as soymilk machines and juicers, stainless steel filters are also used to filter residues.

Aquaculture: used in the filter system of fish tanks to filter out impurities, feces, etc. in the water, keep the water quality in the fish tank clean, and provide a good living environment for aquatic organisms.

Specifications of stainless steel filter:

Mesh: Mesh is an important specification parameter of stainless steel filter, which refers to the number of holes in a length of 1 inch (25.4 mm). Common meshes are 10 mesh, 20 mesh, 40 mesh, 60 mesh, 80 mesh, 100 mesh, 200 mesh, 300 mesh and up to 4000 mesh.

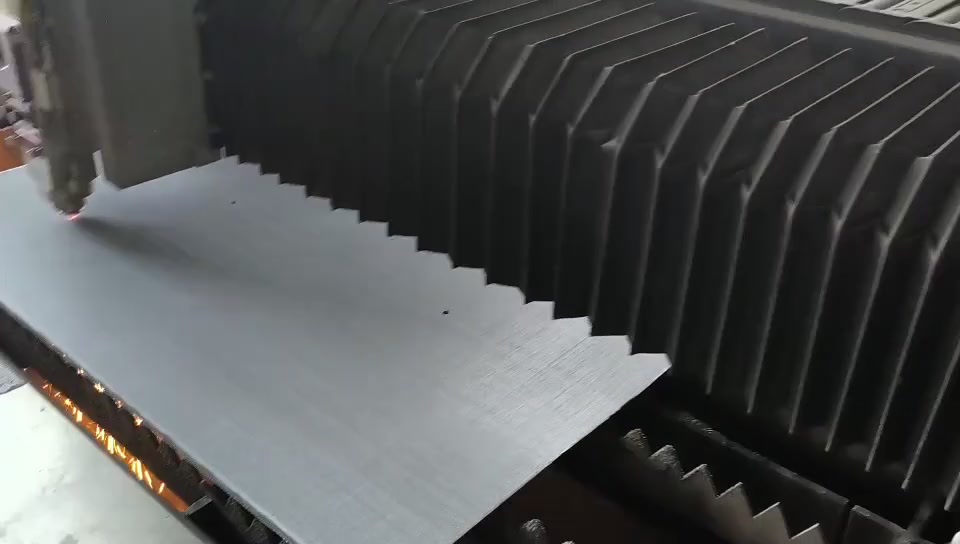

Wire diameter: The diameter of the stainless steel wire that makes up the filter, usually in millimeters. The thickness of the wire diameter will affect the strength, filtration accuracy and service life of the filter. Common wire diameters range from 0.03 mm to 15 mm.

Aperture: refers to the diameter or size of the mesh on the filter, which determines the size of the particles that can pass through the filter, and the unit can be millimeters or microns.

Material: Common stainless steel filter materials include 304, 316, 316L, etc. 304 material has good corrosion resistance and processing performance, suitable for general industrial and living environments; 316 material has stronger corrosion resistance and is suitable for some environments with high corrosion resistance requirements, such as marine environments.

Size:

The size of the filter includes width, length and thickness. The width is generally between 1 meter and 10 meters, the length can be customized according to customer needs, and the thickness depends on the specific usage scenario and requirements.

Weaving method:

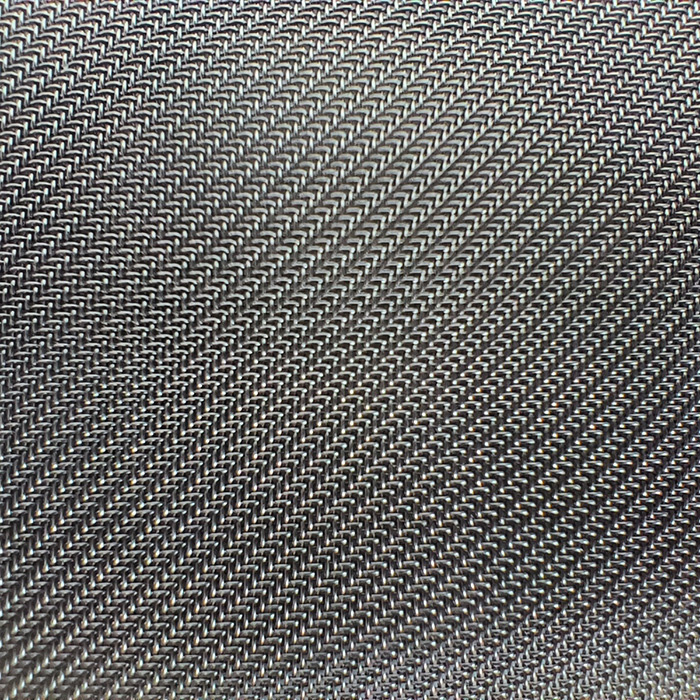

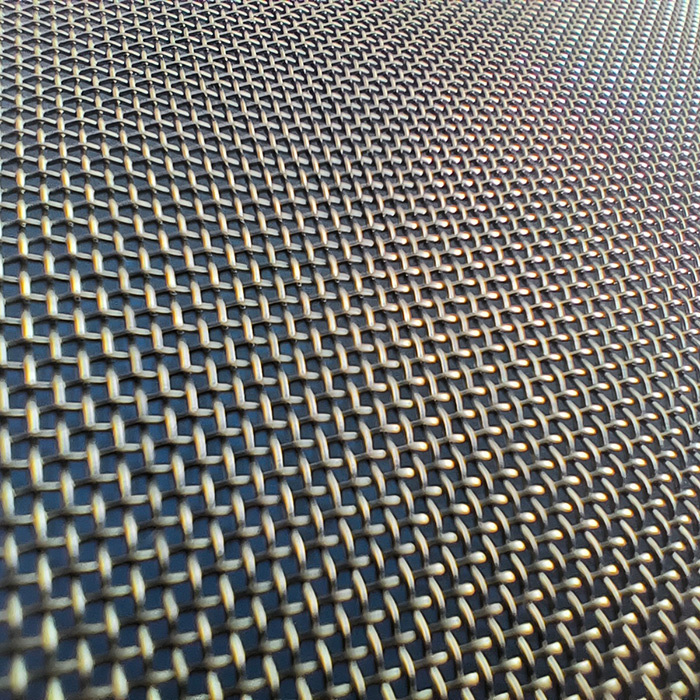

Mainly plain weave, twill weave, dense weave, mat weave, etc. The mesh size of plain weave is uniform and the filtration accuracy is high; the filter mesh of twill weave has high strength and good flexibility; the filtration accuracy of dense weave is very high; the mat weave combines the characteristics of plain and twill, with high strength and filtration accuracy.

Key words:

Stainless steel mesh、Sintered mesh、Filter element、Nickel Mesh & Copper Mesh

Previous

Next

Previous

Next

RELATED PRODUCTS

CONSULTATION

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!

WhatsApp:

Tel:

Address:

No.52, Weier Road, high tech Industrial Development Zone, Anping County, Hengshui City, Hebei Province

Copyright © kangxinlong wire mesh Manufacturing Co., Ltd. Powered by:www.300.cn SEO license